Top reasons to choose used bulk containers for practical business operations

Wiki Article

Just How Mass Containers Can Improve Effectiveness in Your Packaging Procedures

Bulk containers play an essential role in enhancing product packaging operations. Their layout enables far better usage of upright area and advertises arranged stock monitoring. This efficiency brings about minimized material replenishment regularity and lower labor expenses. Furthermore, the resilience of these containers reduces item damage. As businesses look for means to boost their processes, recognizing the diverse benefits of bulk containers comes to be important. What other benefits might they give the table?Streamlined Storage Solutions

As firms look for to enhance their procedures, structured storage remedies have come to be essential for enhancing product packaging effectiveness. Reliable storage space not just saves space but additionally promotes quicker access to products, which is crucial in busy manufacturing settings. Bulk containers, designed for simple piling and company, considerably decrease the complexity of storage systems. They permit businesses to maximize vertical space while lessening the footprint needed for inventory.In addition, these containers frequently feature ergonomic layouts that streamline managing and transportation, reducing the danger of injury and enhancing workflow. By consolidating materials wholesale containers, firms can lower the frequency of restocking and enhance their supply chain processes. In general, the application of effective storage space solutions promotes a much more orderly work space, resulting in boosted efficiency and decreased functional prices. Via thoughtful layout and strategic usage of bulk containers, services can attain significant enhancements in their packaging procedures.

Waste Decrease and Sustainability

While the pursuit of performance typically drives product packaging decisions, waste reduction and sustainability have actually arised as essential considerations in modern operations. Firms significantly recognize that embracing bulk containers can considerably lessen material waste. These containers typically make use of less product packaging material than typical approaches, leading to a smaller sized carbon footprint.In addition, bulk containers can be recycled multiple times, which further lowers the demand for single-use product packaging and minimizes general waste going into landfills. Their design frequently permits less complicated recycling procedures, lining up with sustainability goals.

In addition, firms that focus on waste reduction can enhance their brand name reputation, interesting eco conscious customers. By carrying out mass containers, businesses not just simplify operations however also contribute favorably to environmental stewardship. This dual benefit of functional performance and sustainability settings business positively in an open market progressively concentrated on environment-friendly methods.

Enhanced Setting Up Line Efficiency

Applying bulk containers on assembly lines greatly boosts effectiveness by improving the handling and transport of materials. By using bulk containers, makers can decrease the frequency of product replenishment, permitting employees to concentrate on assembly tasks as opposed to continuous supply management. This leads to fewer disturbances and a smoother workflow, inevitably enhancing performance.

In addition, bulk containers are developed for very easy integration with automated systems, further optimizing the assembly process. Their standard sizes and forms promote far better company, making it possible for workers to situate and access products rapidly. This decrease in search time adds to a more fluid manufacturing setting.

Price Savings and Boosted Earnings Margins

Noteworthy expense savings can be realized via the fostering of mass containers in product packaging procedures. By decreasing the requirement for numerous smaller bundles, companies can reduce product expenses especially. Mass containers frequently need less packaging product overall, leading to reduced expenditures on materials. Additionally, the efficiency of mass handling reduces labor expenses related to packing and unpacking, further enhancing savings.Less journeys to providers and decreased transportation costs are additionally vital benefits, as mass containers allow for raised product capacity per shipment. This greater quantity not just reduces down on delivery expenditures but likewise enhances storage space within facilities, causing boosted stock management.

The longevity of mass containers frequently equates to reduce damage prices throughout handling and transportation, protecting product stability and reducing waste. Collectively, these elements add to improved profit margins, making bulk containers a financially helpful option for services seeking efficiency in their product packaging operations.

Convenience Throughout Industries

Bulk containers supply amazing adaptability across numerous sectors, making them a beneficial asset beyond just set you back financial savings. In the food and drink sector, these containers help with the secure transportation and storage space of big quantities of ingredients, enhancing performance in manufacturing lines. In pharmaceuticals, mass containers guarantee conformity with rigorous hygiene requirements while accommodating the mass handling of basic materials. The chemical industry also benefits, as these containers endure harsh materials and prevent contamination, supporting risk-free operations. refurbished bulk containers. Furthermore, the farming market utilizes check this bulk containers for transferring plant foods and grains, minimizing and enhancing logistics waste. Their adaptability reaches manufacturing, where mass containers streamline setting up procedures and minimize the requirement for excessive product packaging. This cross-industry capability not just improves operational efficiency however additionally promotes sustainability with lowered product packaging waste, highlighting the indispensable role mass containers play in modern-day supply chainsRegularly Asked Questions

view itExactly How Do Bulk Containers Impact Employee Safety And Security in Product Packaging Procedures?

Mass containers considerably improve worker safety and security in packaging operations by lowering hands-on handling, minimizing injury threats, and advertising ergonomic practices. Their style facilitates much safer transport and storage, eventually producing an extra safe workplace for all staff members.

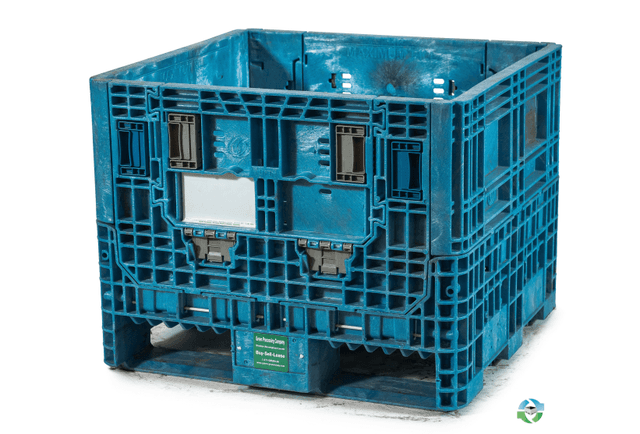

What Materials Are Bulk Containers Usually Made From?

Bulk containers are normally made from long lasting materials such as high-density polyethylene, wood, steel, or polypropylene - used collapsible containers. These products provide strength, resistance to environmental elements, and viability for various components, ensuring efficient and risk-free transport of products

Can Bulk Containers Be Personalized for Specific Products?

Yes, bulk containers can be tailored for specific products. Makers typically tailor dimensions, products, and includes to meet distinct demands, making certain suitable protection and get redirected here efficiency during storage space and transport of various products.Just How Do Bulk Containers Affect Transport Logistics?

Bulk containers simplify transportation logistics by maximizing cargo space, minimizing the number of journeys needed, and reducing dealing with expenses (used collapsible bulk containers). Their standard measurements promote efficient filling and dumping, ultimately bring about enhanced functional effectiveness throughout the supply chainWhat Is the Lifespan of Bulk Containers in Normal Use?

The life expectancy of mass containers in routine use typically ranges from five to 10 years, relying on worldly quality, handling methods, and environmental problems. Correct upkeep can greatly prolong their usability and performance.Carrying out bulk containers on setting up lines considerably improves efficiency by improving the handling and transportation of materials. Bulk containers usually need much less packaging product generally, resulting in lower expenses on products. In drugs, mass containers assure conformity with rigorous health criteria while fitting the bulk handling of raw materials. Their adaptability extends to production, where mass containers improve setting up procedures and reduce the requirement for excessive packaging. Mass containers greatly enhance staff member security in packaging procedures by reducing hand-operated handling, reducing injury dangers, and advertising ergonomic techniques.

Report this wiki page